We launched connected worker safety technology in 2017. Recently we deployed hi-tech systems in a fuel terminal & geothermal power station…

In 2017 we launched our first ‘connected worker safety’ technologies to the New Zealand gas detection market with our latest products from Industrial Scientific.

The addition of peer-to-peer and peer-to-cloud communication technologies was a significant evolutionary step. It’s probably fair to say that this has revolutionised the effectiveness of gas detection equipment.

What does ‘connected worker safety’ mean?

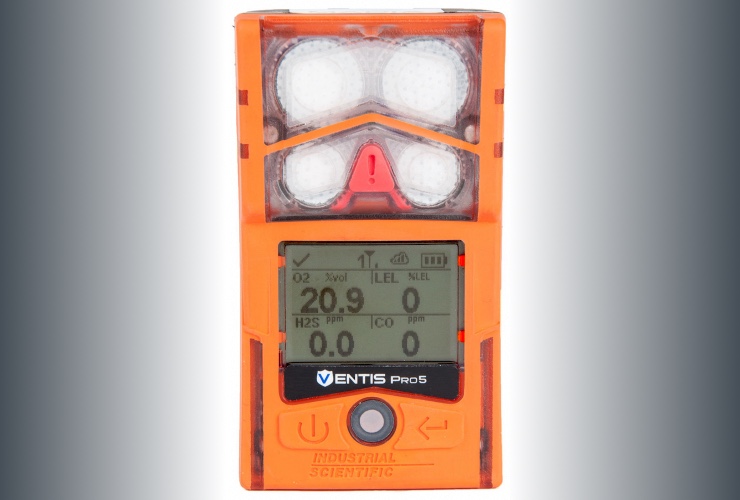

For decades, gas detection manufacturers have been improving the reliability, accuracy and durability of portable gas detectors. These are mature and well-proven products and they are a crucial tool in ensuring the safety of front-line workers.

When a flammable or toxic gas atmosphere is sensed, the gas detector should sound a loud alarm – what we flippantly refer to in the industry as, “See gas, go beep“.

But what happens if there’s no-one nearby to hear the alarm? Or if it’s drowned out by other noise? Or if there are multiple detectors going off and the responder doesn’t know which way to turn?

And, in what can be the worst case scenario, what if the well-intentioned responder goes to assist but doesn’t recognise the exact risks involved and place themselves in harm’s way as well?

Or what if the person involved is working remotely and there’s no-one to hear an alarm, or know if they’ve been incapacitated?

Connected worker safety provides connection amongst team members. Our portable gas detectors and area gas monitors link together using LENS Wireless.

If Bill’s gas detector goes into alarm and Jane’s gas detector is wirelessly connected to it, Jane will be alerted that Bill’s detector is in alarm. Not only that, she can see why it’s in alarm. She can therefore make a considered decision on the best way to respond.

Or, if an area gas monitor that is guarding a particular area goes into alarm, all portable gas detectors connected to it will also be notified.

It goes further than that too. These devices can connect straight to the cloud via a Bluetooth connection with a phone (in a non-hazardous environment) or through built-in WiFi or via a hazardous-rated gateway.

The location and alarm status of all connected workers can be viewed on any web browser anywhere in the world. Any alarm events are notified to the designated people on screen, by txt or email.

Are connected worker safety solutions complicated?

Not at all. The LENS Wireless system is configured “right out of the box”. The procedure to connect detectors manually into a network takes just a few seconds, or the instruments can be set up to connect automatically.

All of our connected worker safety equipment carries the applicable intrinsically safe ratings for the New Zealand market.

But wait, there’s more…

Not only can we report to “Device ABC” that “Device DEF” is in alarm, we can personalise that information to a person’s name.

Back to our scenario before, Bill and Jane might be part of a 10 person team spread around a large workplace.

Bill doesn’t need to know which device number is assigned to which person. The gas detectors can be personally tagged to people and locations with the use of our iAssign tags.

Bill and Jane would each have their own tags, and tags can be placed on key locations as well. In this way, Jane will know which of her team mates is in alarm, and which part of the plant they are located in as well.

Are connected worker safety systems actually being used?

Absolutely. It’s not required in every gas detection application, but we have plenty of customers using these features every day of the week.

In recent months we’ve deployed area gas monitors and portable gas detectors that use LENS Wireless for a large team of contractors refurbishing tanks in a fuel terminal.

As well as being alerted to the normal flammable and toxic gas risks, they are also using this equipment to check the integrity of nitrogen purging to ensure the risk of explosion is contained.

We also have LENS Wireless equipment deployed in the geothermal power sector, protecting teams of operations and maintenance workers by ensuring adequate oxygen, and detecting any presence of carbon dioxide and hydrogen sulphide.

To conclude

Back to our opening question; is this evolutionary or revolutionary. Actually, it really doesn’t matter. All that matters is that these technologies are available now to help ensure everyone goes home safely at the end of every working day.

For more info, get in touch with the connected worker safety experts…

- Email gas@entec.co.nz, or

- Phone (06) 758-3030 ext 2 to talk to a connected worker safety expert.