Workers are now better equipped than ever to practice team-based safety thanks to the ability of devices to communicate with other equipment. Here’s how…

It’s easy to understand that we’re more connected than ever in our personal lives. The same thing is happening in our working lives too. Your location can be pinpointed. Your driving smoothness and safety can be identified.

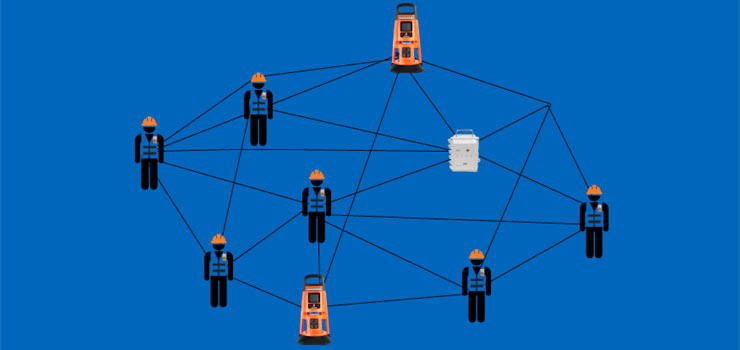

The ever-increasing ability for work-related devices such as gas detectors to connect and communicate with other equipment is having a big impact on worker safety. Quite simply, teams of workers are now better equipped than ever before to keep each other safe.

The latest portable gas detection products from Industrial Scientific are loaded with communication options, which results in…

- Decreased response times in the event of an alarm or emergency.

- Easy deployment with minimal setup – they work “right out of the box”.

- Teams are connected together, so alarm events are notified across the whole team.

- Continuous communication, both at the work front and remotely – other workers in a control room or marshalling point are in touch with all of their colleagues.

Team-based safety in action

Industrial Scientific’s Ventis Pro range of multi-gas detectors, and the Radius BZ-1 area monitor, can all be linked together using LENS Wireless. When any instrument goes into alarm, all the other linked instruments also go into alarm.

They not only notify all users that there is an alarm, but they detail who is in alarm, and what the alarm event is.

This is critical. It means that co-workers are well-informed and can plan an effective and safe response. All too many people have died around the world in industrial accidents where they’ve mounted a well-intentioned but poorly-informed rescue.

As well as units in the field being linked together, they can also communicate off-site via the cloud. With gateway devices installed on-site (or with the soon-to-be-released WiFi version of Ventis Pro) data from the instrument (including its position via GPS) is displayed on the iNet Now dashboard.

A safety manager, or a shift supervisor, or indeed anyone anywhere in the world with an internet connection, can see the location and the status of a team of workers.

This data is obviously most useful in real-time to protect people right now. But there’s an additional and totally unexpected benefit…

Portable gas detectors are also turning into environmental data recorders.

Safety, industrial hygiene and process engineers can get access to a wealth of data previously unavailable. The illustration below is an example of a heat map image that can be built over time, with the “hot spots” indicating locations where a greater number of alarms have occurred.

For the best response times… for the most informed rescue operations… for the best in people and plant safety in real time and in the future… the newest gas detectors are bringing team-based safety alive, today.

To find out more about team-based safety and environmental data recorders, here’s what to do…

- Email gas@entec.co.nz, or

- Phone (06) 758-3030 ext 2 to talk to a gas detection expert.